Corten Steel Lifespan

What is the lifespan of Corten Steel?

This is a question we get asked frequently. However, there is no definitive answer. The lifespan of Corten steel is influenced by many factors, including the environment in which it’s placed, its exposure to wet and dry cycles, and the thickness of the steel itself. In the following sections, we’ll look at these factors in more detail to provide a clearer understanding.

Contents

Composition and Corrosion Resistance

Corten steel, while similar to other carbon steels, has the unique attributes that set it apart. In its initial stages, Corten steel starts to rust in much the same way as mild steel does. However, what makes Corten distinct is its far superior resistance to atmospheric corrosion compared to its counterparts. This enhanced resistance can be credited to the special alloying elements added which include chromium, nickel, copper, and phosphorous.

One of the defining characteristics of Corten steel is its ability to form a protective patina layer when it is subjected to alternating wet and dry cycles. This patina is more than just an aesthetic layer; it acts as a barrier, sealing off the steel surface, thereby significantly boosting its resistance to further corrosion. An added advantage is this patina’s ability to self-heal. If the steel is scratched or slightly damaged, the patina can regenerate over the affected area, maintaining its protective function.

The colour of Corten steel evolves from an initial light orange-brown hue to a deeper, dark brown over time. However, this transformation isn’t just a matter of time passing; it’s also highly influenced by the surrounding environment. For instance, in industrial settings, Corten steel tends to weather more quickly and develop a darker final colour compared to rural areas.

Corten steel thrives in places where the weather alternates between wet and dry periods. These cycles help to develop and maintain the material’s protective layer. In places such as the UK, where these cycles are common, the protective layer establishes itself more quickly, speeding up the overall process of oxidation.

Rate of material loss

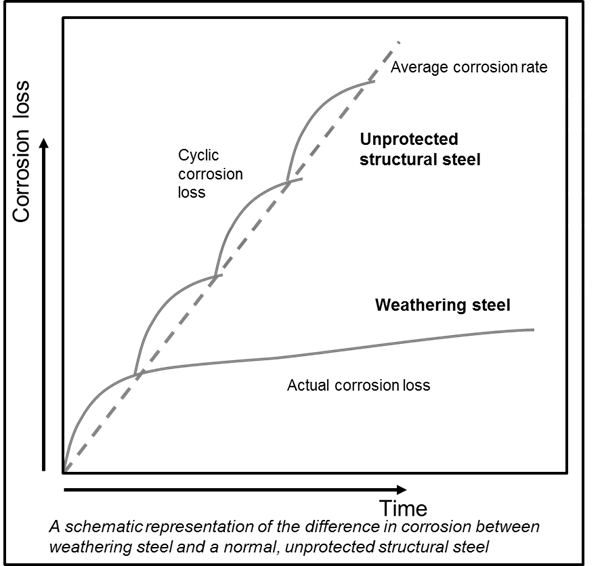

As indicated by the chart Corten steel has a considerably slower corrosion rate compared to other types of carbon steel. Interestingly, the process of material loss is not linear. About 80% of material loss typically occurs within the early years of its lifespan.

Originally developed to eliminate frequent and costly maintenance like painting, Corten is at its best when left in its natural state, especially for landscape products. This means allowing it to weather outdoors, untouched and uncoated. However, for specific applications, like the inside of a corten steel retaining wall or planters that might not undergo regular wet-dry cycles, there is an argument to use a protective coating such as a bitumen paint or simply go up a thickness in material to allow for any material loss but these do both come with an additional cost and are only recommended for projects demanding exceptionally long life spans of 40+ years which we don’t get asked for very often.

ISO 9223:2012 Corrosion Standards

According to the ISO 9223:2012 standard for corrosion of metals and alloys, atmospheric conditions are classified as follows:

- C1 Very Low: Mostly indoor environments with low levels of pollution.

- C2 Low: Atmospheres with low levels of pollution. Mostly rural areas.

- C3 Medium: Urban and industrial atmospheres. Coastal areas with low salinity.

- C4 High: Industrial and coastal regions with moderate salinity.

- C5 Very High: Atmospheres with high pollution. Coastal and offshore areas with high salinity.

Corrosion Allowances

According to the ‘Standards for Highways CD 361 – Weathering steel for highway structures,’ corrosion allowances have been defined for different environmental categories. For a lifespan of 120 years with both faces of the material exposed, the following allowances apply:

- C2: 1mm

- C3: 2mm

- C4: 3mm

So, based on this information, adding 1mm of thickness should cover any corrosion loss over a 40- year period in a C2-C4 environment. For example, you can expect one of our 3mm thick Corten Planters to be approximately 2mm thick after 40 years of weathering from both sides.

In C5 environments exposure to high concentrations of chloride ions from seawater can greatly affect the protective oxide layer as it maintains a continuously damp environment on the metal surface. As a result, Corten would continue to corrode at a similar rate as other carbon steels.

Historical evidence of durability

Corten steel’s impressive durability is evident in its historical applications. One of its earliest architectural uses was in the construction of the John Deere World Headquarters building in Illinois, US which opened its doors in 1964. Across the UK, structures made from Corten, including bridges that are still standing strong after 50+ years and iconic sculptures like the ‘Angel of the North’ in Gateshead, highlight the material’s longevity and resilience. Continuously exposed to the elements, these structures serve as a testament to Corten’s enduring strength and aesthetic charm.