Metal Edging Strips

£123.00

![]()

- Get an instant price using the calculator below.

- Plain metal strips cut to size available in mild steel or corten steel.

- Please note all of our edging strips are supplied unweathered.

Current lead time is 1 week

Product Information

Transform your garden with our custom Metal Edging Strips, available in mild steel and corten steel with thicknesses of 3mm and 5mm. Cut to your exact specifications, these versatile strips are perfect for defining borders, creating clean lines, and separating garden spaces. Ideal for DIY enthusiasts, they offer a sleek, durable solution for a variety of landscaping and design needs.

Information

| Finish | Unweathered – this product may have began its weathering process on dispatch and will continue to weather for around 6-9 months. |

|---|---|

| Maintenance | No maintenance required |

| Material | Mild Steel, Corten Steel |

| Steel Thickness | 3mm, 5mm |

About Corten

Please note that we may dispatch a Corten Steel product at any stage of its weathering process.

What is Corten Steel?

Corten steel, which is also known as ‘weathering steel’, is a group of steel alloys that were originally developed to eliminate the need for painting or applying protective coatings to steel surfaces. So, what truly sets Corten Steel apart from its peers? When subjected to atmospheric elements, this remarkable material develops a protective layer resembling rust on its surface. This unique characteristic makes it highly resistant to corrosion.

This innovative material was first brought to life back in the 1930s. Its primary application was within the railroad industry, and it was subsequently patented by the well-known U.S. Steel (USS). Interestingly, the name “COR-TEN” stands for the material’s two primary properties. ‘Cor’ signifies Corrosion Resistance, while ‘Ten’ indicates Tensile Strength.

What is Corten Steel Made of?

Primarily composed of iron and a small amount of carbon, Corten steel sets itself apart due to the inclusion of unique alloying elements: chromium, nickel, copper and added phosphorous which gives the steel its self-protecting properties. A particularly noteworthy feature of this composition is the ability of the materials outer layer to naturally repair itself when subjected to scratches or damage, demonstrating its resilience and longevity.

Is Corten Steel Expensive?

Although Corten steel might come with a higher upfront cost when compared to mild steel, it turns out to be an economical choice in the long run. Given its resilience and low maintenance requirements, your investment in Corten steel recoups itself as time goes by.

Furthermore, when you consider the expenses associated with protecting other sheet metals via processes like painting or galvanizing, the price difference starts to level out, reaffirming the cost-effectiveness of Corten steel.

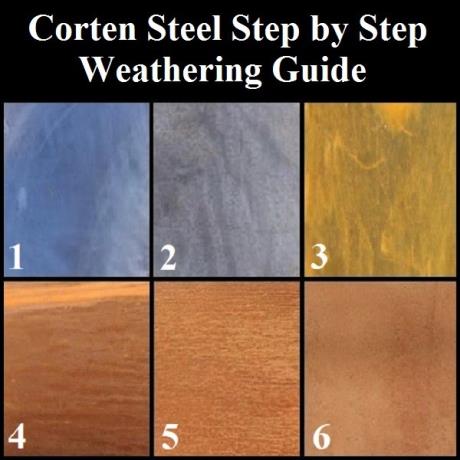

How does Corten Steel Weather?

One of the fascinating aspects of Corten steel is its weathering process, which typically takes around 6-9 months, depending on the prevailing weather conditions. At the start of the process, the steel develops an orange patina. As time goes on, this turns into a darker brown hue, providing Corten steel its iconic look. It’s important to note that Corten steel requires a cycle of alternating wet and dry conditions to form this protective layer effectively.

Step 1 – Newly created Corten Steel. At this point, a dark, oily coating is visible on the Corten Steel.

Step 2 – The dark coating starts to degrade, marking the start of Corten Steel’s weathering process.

Steps 3 & 4 – The “Run-Off” phase. This stage can take between 3 to 9 months, depending on weather conditions and location.

Steps 5 & 6 – During these final phases of weathering, occasional ‘run-off’ may still occur. Meanwhile, Corten Steel’s patina evolves towards a more uniform and striking appearance.

Where is Corten Steel used?

Corten steel’s unique properties have led to its use across a range of industries, including architecture, construction, and landscape. You’ve probably seen it in the form of large structures like bridges, or even the Angel of the North, a renowned sculpture. But Corten steel isn’t limited to grand structures alone. It’s also become very popular in recent years for creating outdoor garden products such as corten planters, edging, artwork, water features, and street furniture, adding a natural and rustic aesthetic to any outdoor space.

Run-Off

Another significant aspect to understand about Corten steel is the occurrence of ‘run-off’ during the initial stages of its weathering process. ‘Run off’ refers to the rusty water that can drain off from Corten steel, potentially causing staining on the surfaces upon which it is placed.

To ensure that run-off doesn’t become a concern, there are several steps you can take:

- Complete Weathering Before Placement: You could allow the Corten steel product to undergo the complete weathering process and let any run-off occur before positioning it in its final location. If you’re aiming for a more rapid transition, you could apply a weathering treatment to speed up this process.

- Use Protective Layer: Alternatively, you might consider placing the Corten steel product on a slab or other protective material that can be moved or replaced once the product has fully weathered. This acts as a barrier, protecting your surfaces from potential staining.

- Opt for Easily Replaceable Materials: Lastly, you could choose to position the Corten steel product on grass or soil which won’t cause any issues or loose materials such as stone, slate, or wood chippings. These materials can easily be turned over or replaced to eliminate any run-off stains.

The weathering process of this product is integral to it and as such we will not accept any responsibility for damage caused to surrounding materials as a result of run-off.

About Mild Steel

Mild steel is the most commonly used and widely available low carbon steel on the market and is typically used in projects where a large quantity is required, such as in structural projects. The materials high strength, flexibility and low cost make it a very economical solution.

- Appearance

At the very beginning, both Corten steel and mild steel look very similar, and there is not much difference between the two. However, exposure to the elements begins the weathering process, and this is where the first major difference starts to appear.

Corten will develop a beautiful orange patina as the weathering process begins, while mild steel will produce a darker brown appearance instead. Over time, both will slowly develop a lovely brown patina when the weathering process is complete, but it will take mild steel a lot longer to reach this stage in comparison to Corten.

- Corrosion

Although both mild steel and Corten steel do look similar after the complete weathering process, they do have very different corrosion results.

Over time, Corten will develop its own unique layer of rust on the surface, which effectively acts as a protective barrier that prevents the steel itself from corroding. The weathering process takes around 6-9 months, and Corten steel products are incredibly durable and long-lasting, degrading at a significantly slower pace than other steel options.

Mild steel does not have that same effect, which means when exposed to the elements, it will begin to corrode at a much faster rate and will require replacement sooner. The weathering process will take around 12-18 months to complete.

- Cost

Another major difference between Corten steel and mild steel is their price point. Mild steel is a very affordable solution, whereas our Corten products will typically cost around 50% more on average.

While this can require a higher initial investment, Corten steel is able to last longer and often has a more attractive finish, which makes it a popular choice for use in both commercial and residential settings.